- 1 X-Ray machine

- 1 Mass spectrometer

- 2 CMM tri-dimensional measuring machine

- Several leak proof test devices

- 2 Transfer machines with artificial vision, weight measurement and threads deburring

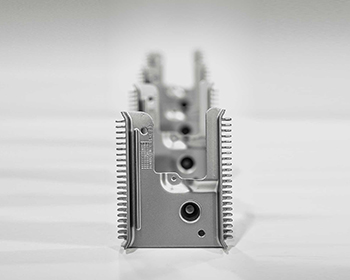

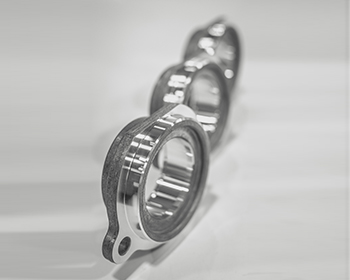

Fundínio, S.A. produces aluminium high pressure die casting parts for the automotive industry, telecommunications, rail transportation, and others, that require high technical skills. As support activities we have developed an important know-how in machining, assembling and painting (outsource), providing a wide range of possibilities for our clients’ projects.

Produce Aluminum parts by High Pressure Die Casting process, generating value for the interested parties.

Competence, Accuracy, Teamwork, Flexibility, Agility, Ethics in business, Competitiveness.

To be an engineering company specialized in Aluminium High Pressure Die Casting solutions, with machining and surface finishing.

Our history goes back to 1969 with the foundation of INDUFER, a pioneer in Portugal in high pressure aluminium die casting. At the time our main business activity was the production of home appliances, ironware and cutlery.

In 1984 with the new company designation EMOAÇO we have begun working for the automotive and lighting industries.

Fundínio is born in 1995 as a result of a company bailout program, absorving all of Emoaço, and keeping its line of business.

Today we continue our work with the automotive industry but we have expanded our client base to other industries such as the electronics, rail transportation, medical equipment and fluid control valves which demand high technical skills. We currently employ 90 workers within a facility of 11.600 m2 including 7.700m2 of built area in Senhora da Hora, 2 km away from Porto, minutes away from the city's harbour and the international airport.

We are pleased to present you a glimpse of our work.

Our very experienced engineering department supports every step of the project, from die's design to the final part, including machining, assembling and painting or other surface finishing. We are well equipped with HPDC machines ranging from 250 to 1600 ton and a team of experts in this field.

FUNDÍNIO, S.A. has an Integrated Management System of quality and environment, supported by the IATF16949 and ISO 14001 standards and is committed to continuous fulfillment and improvement of:

View / Download certification - PDF

Fundínio SA is always ready to help customers, so please contact us within our working hours and we are always at your disposal for any questions and help you solve any problem.